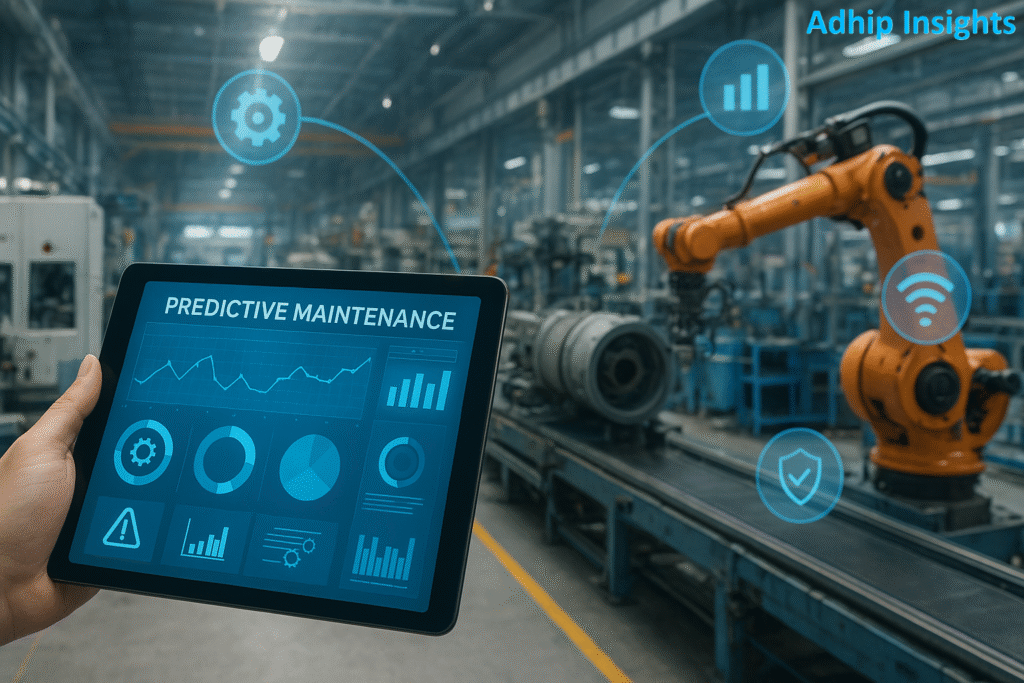

The modern industrial environment is ever changing and competitive and the factory is no longer an area where engines are working to a fixed program. Modern factories are smart, connected and data-driven – and at the center of this evolution sits predictive maintenance. Once you have an interest in how to mitigate expensive downtimes, how to enhance the performance of the equipment, and how to increase the productivity, predictive maintenance is one of the most powerful tools a smart factory can utilize. In this blog post, we will discuss how predictive maintenance functions, why it is an important element of the Industry 4.0, and how it can bring quantifiable improvements to manufacturers.

What is Predictive Maintenance?

The predictive maintenance strategy is a proactive maintenance system in which real-time data are used to determine the likelihood of what equipment will fail and perform maintenance in advance because it will become inoperable. Predictive maintenance is different to traditional (correction-based) or preventive maintenance (scheduled-based) in that it uses IOT sensors, machine learning and big data analytics to assess the condition of equipment and when maintenance is actually necessary.

Smart factory means that the machines in such factory would have sensors installed that would measure indicators like vibration, temperature, pressure, sound or electrical current as indicators of performance. The sensor data tapered by these sensors is relayed to a cloud or an edge system. It is there where the advanced analytics and machine learning are used to find abnormal trends and perceive signs that indicate a possible fault. Once an anomaly is identified, system alerts are sounded and recommendations given to the maintenance teams to ensure their response is immediate and accurate.

Why predictive maintenance is necessary in smart factories.

The modern idea of the smart factory is hinged upon the idea of connectivity, automation and efficiency – and predictive maintenance optimizes each.

- Decreased Unplanned Downtime

Loss of equipment at its peak production is the nightmare of every factory manager. Unforeseen failure causes delays of the production, delayed delivery date and discontented customer. The latter is minimized by several orders of magnitude with predictive maintenance because the patterns of the failure can be detected in time and then their teams can repair or replace them before the defect occurs. Deloitte has reported that predictive maintenance has the potential to minimize the number of unforeseen downtimes up to 50%.

- Reduced Maintenance costs

Under conventional preventive maintenance, technicians will repair or replace parts that do not have to be replaced, because the maintenance schedule dictates so. Predictive maintenance prevents useless replacements and enables teams to maximize the use of parts. The outcome is reduced cost on spare parts and Maintenance activity that is more optimized.

- Better quality of products

The products produced by machines that every time produce their top performance will have quality products. Predictive maintenance can guarantee that equipment stays at peak performance and results in more regular output and lower defect contention.

- Increased Safety

Malfunctions do not only halt operations, but there is a considerable danger of unsound safety in most cases. Predictive maintenance will reduce the risks of failing and result in the manufacturing of a calmer place of work to employees.

How Predictive Maintenance Works in a Smart Factory

A fully integrated predictive maintenance system typically includes the following components:

| Component | Description |

| IOT Sensors | Collect real-time data from machines |

| Connectivity | Transmit the data via wireless or wired networks |

| Data Storage | The data collected should be stored in cloud or edge platforms |

| Analytics Engine | Analyze data and predict failures using AI/ML algorithms |

| Alert & Reporting System | Alert maintenance teams of detected anomalies |

These components operate together constantly. In this example, a machine-learning algorithm can look at vibration patterns in a smart motor. It forecasts the remaining useful life and indicates the impending bearing failure when it notices that something is not going according to the past standards. Maintenance is then planned at the earliest possible production break time – no idle time and no lost income.

How to overcome the problems of Predictive Maintenance.

As positive sides are quite obvious, three implementation obstacles that factories must deal with should be mentioned:

Data Quality: The quality of predictive models will only be as fine as its inputs. There are risks of weak calibration of the sensors and incomplete data sets that compromise results.

Trained Personnel: Maintenance personnel require educational background to have an understanding of the predictive alerts and be able to convert it to action.

Upfront Investment: Sensors, data analytics platforms and integrations need an upfront investment, but have a long-term payback.

The Future: The Digital twins, 5G and autonomous maintenance

The sphere of predictive maintenance is in constant flux. It is even becoming more powerful due to emerging technologies:

Digital Twins enable virtual copies of the machines whose real-time conditions are simulated and the predictability of the outcomes they are applied to made significantly more accurate.

5G Connectivity can provide the blazing speed of data transmission, which can afford real-time monitoring in big scale.

In the near future, AI systems will be able not only to identify issues, but also to solve them automatically through collaborative robots or otherwise automated repair systems through Autonomous Maintenance.

Final Thoughts

Making your factory smarter or increasing your reliability and lowering your costs, predictive maintenance is not a buzzword, it is an effective method. Predictive maintenance transforms raw equipment data into actionable insights, taking downtime and turning it into uptime to truly put manufacturers ahead of their competition.

When you are considering getting intelligent maintenance programs at your facility, collecting data of your critical assets is the first step that you should use. Erect a platform consisting of data entrusted worthy sensor and you will be poised to trustworthy the complete prospect of proactive maintenance.